Features

Various Wired Connectivity options like Ethernet (LAN), RS 485, RS 232, Analog Inputs like 4-20mA Current Loop and 0-10 V etc.

Data capturing from Cloud Server using various IoT protocols such as MQTT, REST APIs, CoAP, WEBHOOK, HTTP, etc.

Data Capturing capability from various Special Purpose Machines like FANUC, ARBURG etc.

Data capturing Capability from All brand of PLCs like Siemens, Rockwell/ Allen Bradley, Delta, Mitsubishi etc.

Various Wireless Connectivity options like WIFI, GPRS, LoRa, BLE, NB-IoT etc.

Data capturing from Various PC software’s and from databases like Oracle, Access, SQL, MONGO DB etc.

Compatibility to variety of Industrial Protocols like MODBUS RTU, TCP/IP MODBUS, Profibus, ProfNet, Ethernet IP, ControlNet, S7 protocol, OPC-UA (If space permits show logos of these protocols to gather attraction)

Rugged Cabinets suitable for harsh Industrial environment with various mounting options such as Hanging, Wall/Foot/ Pole mounting arrangements as per requirement

Product Overview

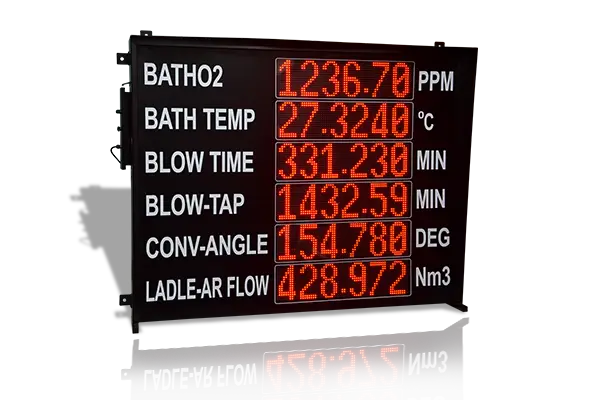

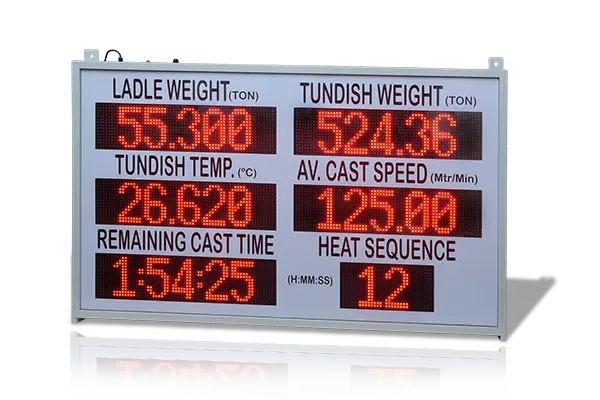

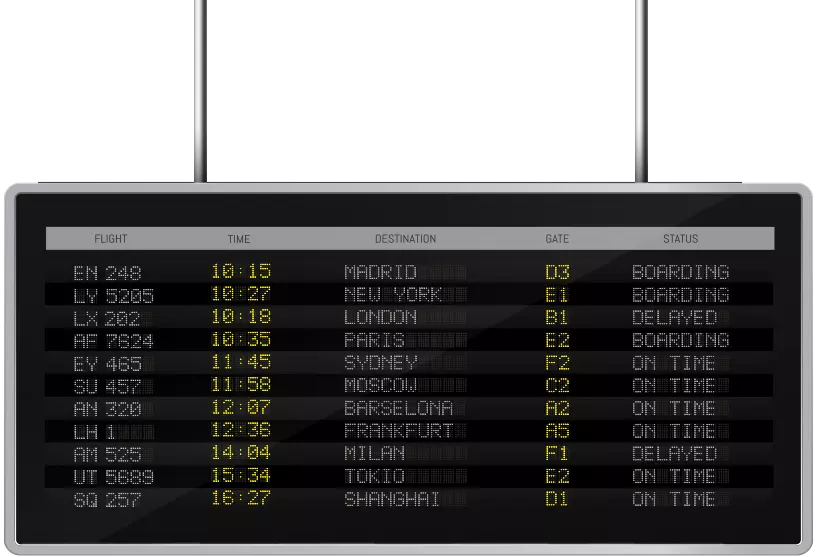

Monitoring various processes is integral part of production process in different process industries such as steel plant, cement, paper, food, pharma etc. It helps production head to check & maintain quality.

Vertaxis provides Parameter Display Solutions to various industry verticals. These displays can be custom-built and can take inputs from various make Data loggers analysers systems, from various makes PLCs and SCADA systems etc. Inputs or Communication interfaces to these displays can be of various types as follows.

Why We Do It Better

- Helps in maintaining and improving quality of the products

- Minimize the production cost

- Reduces variability of materials

- Saves Post Production Cost

- It reduces Process Setup time

- Ensures employee safety

- Lowers the risk of damages to equipment, inventory, and machinery

- Lessens downtime of machines and other equipment

- It reduces Process Setup time